In 2022, photovoltaic cell technology ushered in a critical break point of the changes between old and new. With the conversion efficiency and cost of P-type cells approaching the limits, the mainstream photovoltaic technology has been gradually developing to N-type cell technology with higher theoretical conversion efficiency and greater space for cost reduction and efficiency improvement. The new generation of N-type cell technology represented by Tunnel Oxide Passivated Contact (TOPCon) cell, Heterojunction (HJT) cell and Interdigitated back contact (IBC) cell has gradually become the new "favor" of the industry, and the expansion process of N-type cell has been further accelerated.

At present, N-type cell technical routes are very diversified, but only HJT and TOPCon have been commercialized and applied on a large scale. Domestic leading PV manufacturers have joined into these two camps, and the competition has entered into a white-hot situation. Today, let's figure out which is better, HJT or TOPCon technology.

Transition Technology or Future Technology

TOPCon, with a full name of Tunnel Oxide Passivated Contact, is an N-type cell technology proposed by Fraunhofer Research Institute in Germany in 2013. TOPCon cells use N-type silicon wafer as substrate, prepare an ultra-thin silicon oxide as tunneling layer on the back, and then deposit a thin doped silicon layer, thus forming a passivated contact structure jointly. From the perspective of technology development path, TOPCon is extended from PERC, and has many overlaps in production processes with PERC, so is also called the transition technology from P-type to N-type. For the manufacturers who have laid out PERC cells on a large scale, choosing TOPCon technology route can undertake the original PERC production line to conduct the transformation and upgrading, and has low transformation cost , which can be used as one of the short-term development choices.

Heterojunction (Intrinsic thin film heterojunction cells) is a brand-new cell technology pointing to the future, which has incomparable competitive advantages over TOPCon in the medium and long term. Different from the homojunction formed by diffusion doping on the surface of traditional crystalline silicon solar cells, HJT is a heterojunction formed from two different substances Amorphous Silicon (a-Si) and Crystalline Silicon (c-Si), which has the characteristics of crystalline silicon cells and thin film cells. As an efficient crystalline silicon solar cell, heterojunction has better performance and parameters than those of TOPCon. The natural double-sided symmetrical structure of HJT is beneficial to realize double-sided power generation, and the excellent passivated effect of intrinsic amorphous silicon thin film brings higher open-circuit voltage and photoelectric conversion efficiency than other traditional cells. In addition, HJT has multiple technical advantages, such as high double-sided rate, low temperature coefficient, no light induced degradation (LID) and no potential induced degradation (PID), good weak light response and etc..It has remarkable power generation gain effect in terminal power stations, low LCOE, long life cycle, obvious product performance and market competitiveness.

Production Process, Effective Upon Adopting

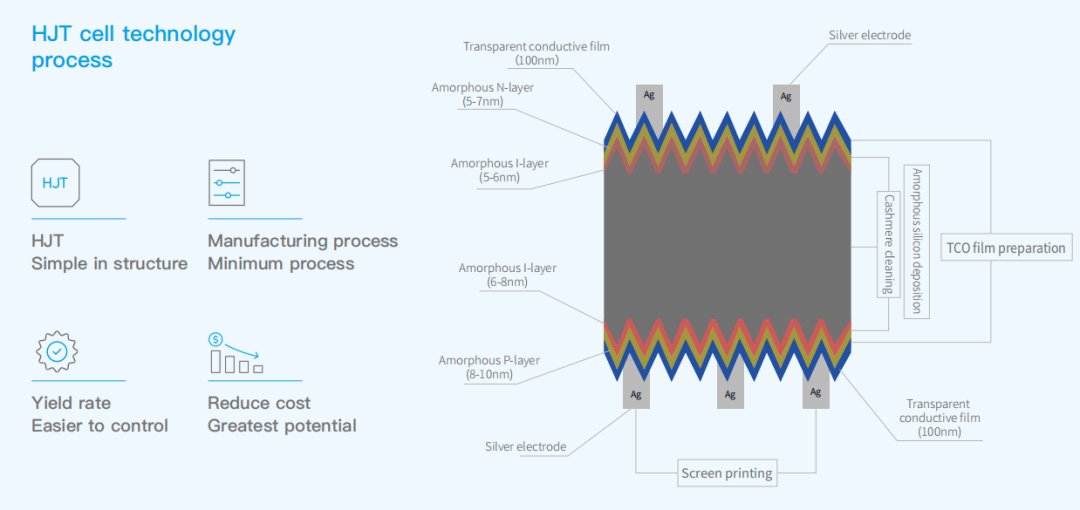

The process steps of photovoltaic cells determine the equipment cost, production yield and mass production difficulty. In the terms of production process, TOPCon has too many production process steps and high process complexity. TOPCon needs 12 production processes, including texturing cleaning, boron diffusion, etching, alumina deposition and etc. The complicated processes bring about the increase in equipment power, floor space and personnel cost. Moreover, the core process of TOPCon, the passivated contact preparation of oxide layer, has a variety of subdivision process routes, such as LPCVD, PECVD, PVD, ALD and etc. The technical routes are inconsistent, and each route has obvious advantages and disadvantages, which bring great difficulties to production line design and process introduction. However, the preparation process steps of heterojunction cells are less and the process is simple, which only needs four steps: texturing cleaning, amorphous silicon film deposition, transparent conductive film deposition and screen printing curing, bring the reduction of production cost and process difficulty.

▲ AKCOME HJT cell technology process

The yield will directly affect the production line efficiency and production cost, and the yield of HJT is significantly higher than that of TOPCon. Because TOPCon adopts high-temperature process and has many process steps, warping, fragments, dark chips, dirt and other problems occur from time to time. The overall yield of TOPCon is only 93-95%, while HJT adopts low-temperature process and has few process steps, with an average yield of over 98%, and the average yield of Akcome HJT cells exceeds 99%.

High Conversion Efficiency Potential

HJT has high conversion efficiency and large space for efficiency improvement in the future.The theoretical conversion efficiency limit of HJT is 27.5%, and the mass production efficiency of HJT in mainstream market is about 24% at present. With the continuous research and development of heterojunction technology and the application of the technologies of micro-crystalline, half-cut and optical injection and etc., the conversion efficiency of HJT mass production is expected to further break through. In terms of technology extension, HJT has the potentialof platform-technology. If IBC process is superimposed to form HBC cells, mass production efficiency is expected to exceed 26-27%; If is superimposed compound cells such as perovskite to form perovskite/HJT laminated cells, the conversion efficiency can exceed 30%. Through superimposed technology, the upper limit of cell photoelectric conversion efficiency can be increased, and the technical life cycle can be effectively lengthened.

Reviewing TOPCon, at present the mass production efficiency of TOPCon in the market is about 24%, and its theoretical limit efficiency is 28.7%. However, this theoretical limit needs to realize double-sided passivated contact technology, which is difficult to realize, and it is difficult for TOPCon to form a lamination with perovskite cells. Therefore, from the view of the medium and long term, TOPCon's future efficiency improvement space is not as large as that of HJT.

Cost Reduction, which is better?

In the paths of cost reduction, from silicon wafer, silver paste to equipment and target materials, the cost reduction route of heterojunction is clear and the space is significant. In the aspect of silicon materials, the symmetrical structure and low-temperature production process of heterojunction make it easy to realize silicon wafer thickness reduction, thus reducing the cost of silicon wafers, the largest cost of cell. The heterojunction adopts half-cut process, which can greatly reduce the thickness of silicon wafers, and the thickness of HJT can be reduced to 100 μm without affecting the efficiency. However, TOPCon cells and modules adopt the whole- cut and large-size process, and the thinning limit of 210 silicon wafers can only reach 140um~150um, and also needs to be tested by boron expansion at ultra-high temperature and severe temperature rising and falling.

AKCOME 210 Half-Cut HJT Cell

In terms of silver pastes, HJT leading enterprises reduce silver consumption and cost by adopting advanced technologies such as domestication substitution of low-temperature silver pastes, silver-claded copper, copper electroplating, multi-busbar and busbar-free. However, silver-claded copper process is only suitable for HJT technology with low temperature process, TOPCon technology with high temperature process cannot be introduced, and the busbar-free is also an exclusive technology of HJT.

In terms of equipment and target materials, with the gradual breakthrough in domestication substitution of equipment and domestic target technologies, the investment cost and target material cost of HJT equipment will be rapidly reduced. In the near future, the manufacturing cost of HJT is expected to be equal to or even win that of PERC, and the cost advantage will be further highlighted.

Standing on the cusp of "Double Carbon", it is a foregone conclusion that new energy represented by photovoltaic and wind power will replace traditional energies. Leading domestic and foreign module enterprises have started the large-scale actions in production and expansion of N-type cells, and has also sounded the clarion calls for large-scale mass production of N-type cell technology. HJT has won the favor of the market for its strong technical advantages and huge space for improving efficiency and reducing costs, and is regarded as the next generation of ultra-efficient mainstream cell technology. With the accelerated maturity of mass production process and the challenging advancement of cost reduction technology, the market share of heterojunction will be greatly increased, and a new era of heterojunction with low-cost and commercial mass production is about to be opened.

Horario de atención: 8: 00-17: 00 en días laborables

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Sede: Sala 901, Edificio 1, No. 1818-2, Wenyi West Road, Calle Yuhang, Distrito de Yuhang, Ciudad de Hangzhou, Provincia de Zhejiang